Featured Project

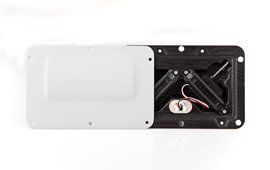

» Project: Servo Mount Enclosure

The Challenge

Our client came to us for the design and manufacture of a light-weight carbon servo mount. As a mission critical component, the product needed to be robust and field serviceable. It also needed to be modular and interchangeable. It had to provide environmental protection for internal components and, like most aerospace applications, had to meet tight space and weight requirements.

The Solution

The key to this project was the integration of servo alignment points, allowing plug-and-play installation for efficient field servicing. Utilizing our proprietary process for modified carbon fiber, we were able to provide enhanced RFI/ EMI protection while still molding delicate features and keeping the part within weight requirements. The overall design solution was robust and readily manufacturable.

By designing the product with fabrication in mind, we were able to take this part from concept to production within a short lead time. Our custom tooling ensured consistent part quality and our secondary assembly services allowed us to deliver a turn-key solution. The end result was a sophisticated product that demonstrated the maturity of design our client needed to win a competitive contract.

All Rights Reserved | Decavo